RENEWABLES

Solar and Wind are driving a significant clean energy revolution in today’s world. Renewable power is a booming sector that brings the benefit of lower emissions of carbon and other types of pollution, thus helping to fight climate change.

In the last years we have matured a strong know-how in Green Power Generation, with special focus on Concentrating Solar Power Plants and in so doing have gained a leading position in such technology.

CONCENTRATING

SOLAR POWER

SOLAR POWER

The Concentrating Solar Power Plant is a renewable technology producing electricity from solar power.

The first mention of the use of concentrating solar power derives from ancient Greece in Sicily (Italy), where Archimedes in 214-212 BC, used bronze shields to concentrate the sun’s rays onto invading Roman ships which, according to the myth, caught fire.

The first documented use of concentrating solar power technology was in 1866, where Augustin Mouchot used parabolic troughs to heat water and produce steam to run the first solar steam engine.

The first operational concentrating solar power plant was built in Sant’Ilario, Italy in 1968 by Professor Giovanni Francia. This plant has architectural similarities to modern plants with its central receiver surrounded by a field of solar collectors.

After more than 2,200 years Fata is building CSP Plants in Sicily, where the myth of concentrating the sun’s rays was born.

The Concentrating Solar Plant consists essentially of special mirrors, that reflect and concentrate sunlight onto a “receiver”. The receiver heats a solution of Molten Salts, up to about 550°C, which are fed to a Steam Generator to produce superheated steam, used in a Steam Turbine to produce electricity.

The advantage of this technology is the possibility to continue the production of electrical energy for up to 24 hours during the night or in absence of sunlight, making use of the hot salts accumulated in the special thermal energy storage (TES) facility.

Moreover a combination plant configuration consisting in CSP technology and classical PV (photovoltaic) technology increases the overall efficiency, optimizing the energy production and self-consumption, and improving the capability of supplying energy continuously.

This scalable source of energy can be used in the following fields of applications:

SOL. IN. PAR S.R.L.

PARTANNA

PARTANNA

The linear mirror collector technology stores the sun’s energy as high-temperature heat to be converted to steam when needed. The steam produced can be fed to a Steam Turbine to produce electrical energy or used directly as thermal energy.

Sunlight is concentrated through linear collectors where parallel rows of flat-glass mirrors reflect direct solar radiation onto a fixed-position receiver unit. The receiver uses vacuum absorber tubes wherein molten salt is pumped and heated to 550°C.

The molten salts, heated by the daytime solar energy, are stored in a Thermal Energy Storage system.

The hot molten salt is used in a Salt/Water Heat Exchanger to convert the collected heat into steam. The total amount of stored energy can be dispatched on a day-ahead basis to match the Customers’ steam demand curve.

The HP steam superheated up to 540°C, is capable of satisfy in the whole range of steam applications.

Highlights:

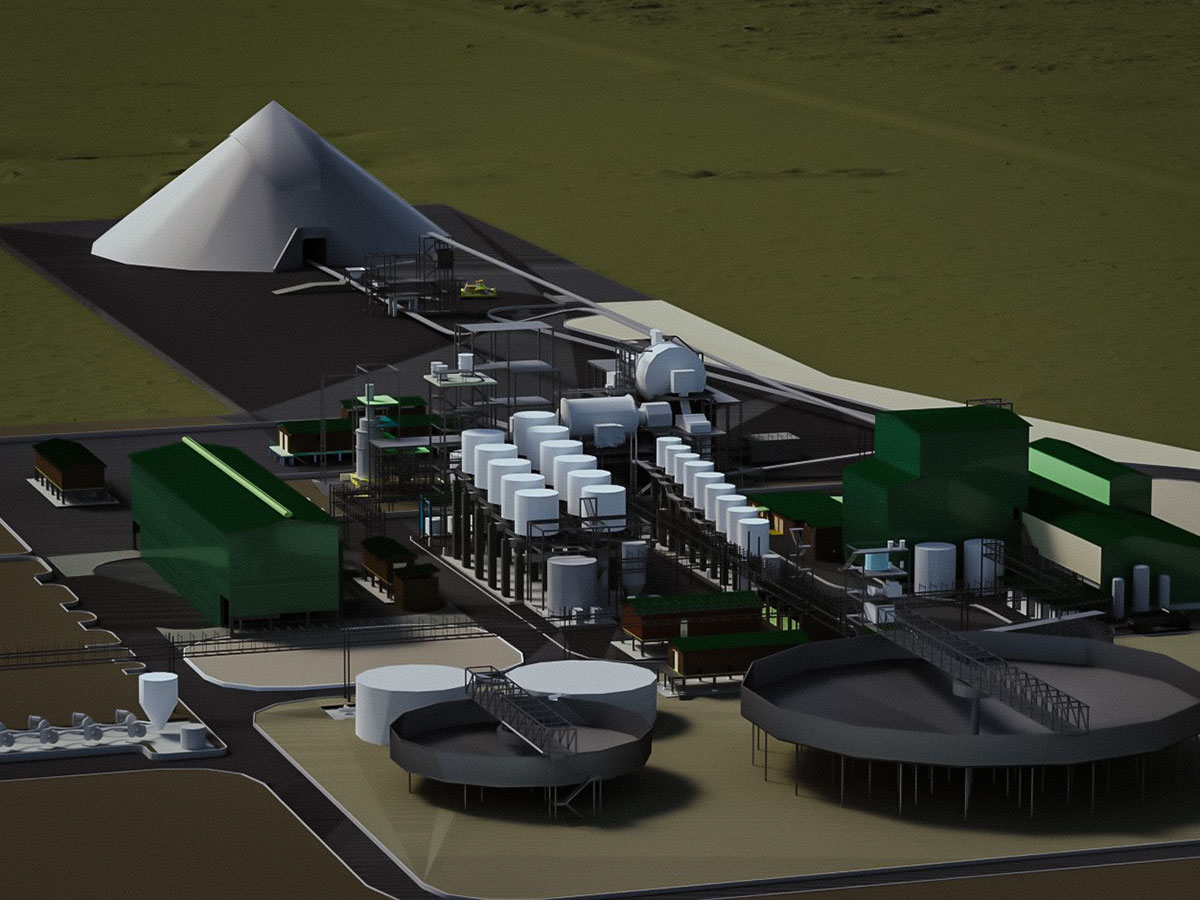

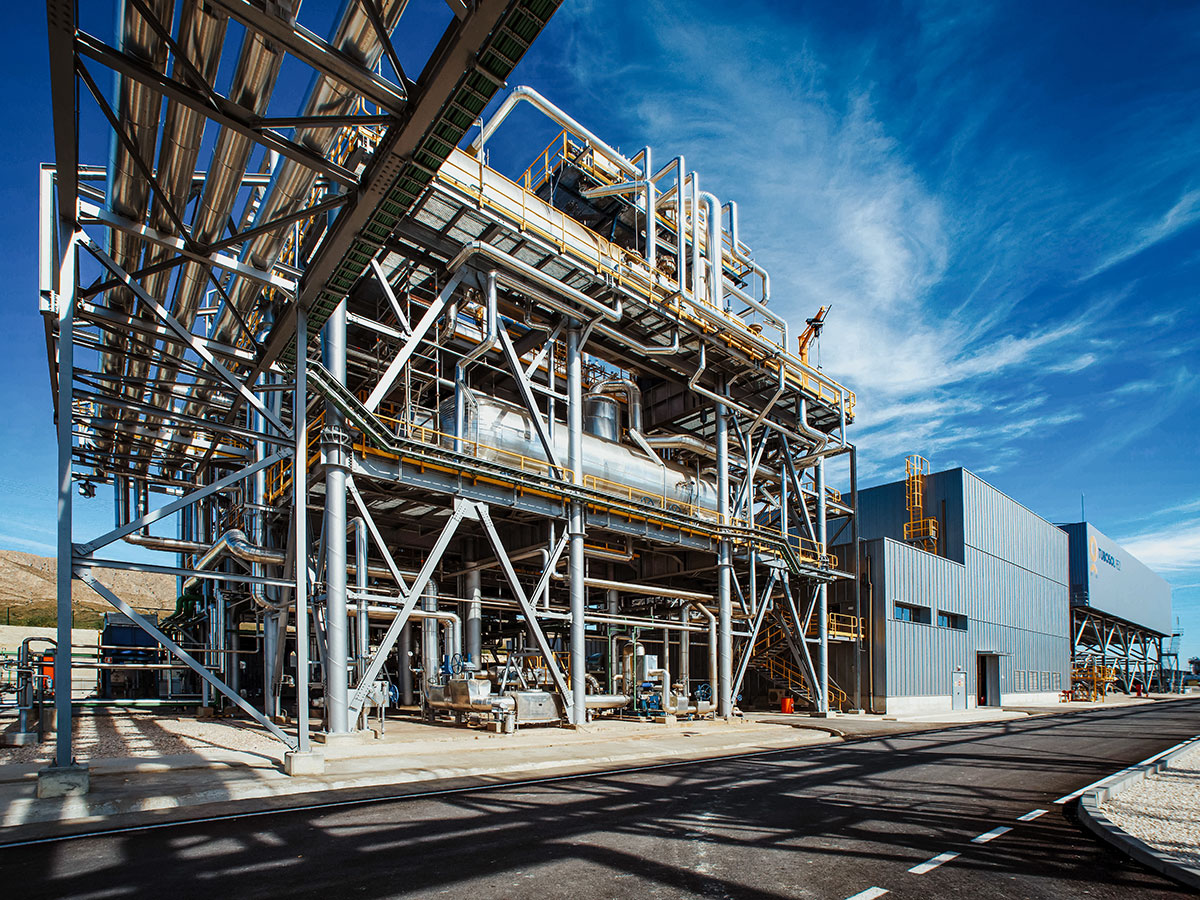

PARTANNA CSP PLANT – 5 MW

Location: Partanna (Trapani), Italy

Client: Sol.In. Par S.R.L.

Role: Main Contractor

Scope of supply: EPC Lump Sum Turn-key for whole plant

Main Eq.: Flat-glass mirror collectors based on Fresnel Technology, molten salt storage, n°1 ST

CONVENTIONAL THERMAL POWER PLANTS

We believe that reliable and stable power generation is the key driver for sustainable economic growth of each Country in the World. Whether located in mature or growing markets, FATA is committed to engineering conventional generation plants by applying the most efficiency technology in order to optimize the usage of natural resources.

FATA has proven experience in providing Engineering, Procurement and Construction services in:

EL-TO CCPP District Heating – 150 MW

Location: Zagreb, Croatia

Client: HEP d.d.

Role: Main Contractor

Scope of supply: EPC Lump Sum Turn-key for whole plant

Main Eq.: n°2 GTs SGT-800 Siemens, n°2 HRSG, n°1 ST

BUTIA – 450 MW CCPP

Location: Kerman, Iran

Client: Butia Iranian Steel Company

Role: Main Contractor

Scope of supply: EP with Site Management and Supervision

Main Eq.: n°1 AE 94.3A GTG, n°1 ST AE (Reheat Type)

AVON PEAKING POWER – 685 MW OCPP

Location: KwaDukuza Municipality, South Africa

Client: Engie, Mitsui

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for BOP (Consortium with Ansaldo Energia)

Main Eq.: n°4 AE 94.2 GTGs (designed to be converted in Combined Cycle)

DEDISA PEAKING POWER – 342 MW OCPP

Location: Port Elizabeth, South Africa

Client: Engie, Mitsui

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for BOP (Consortium with Ansaldo Energia)

Main Eq.: n°2 AE 94.2 GTGs (designed to be converted in Combined Cycle)

TORINO NORD Power Plant – 400 MW CCHP

Location: Turin, Italy

Client: Iren Energia

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for BOP, District Heating System (270MWt), Aux Boiler (340MWt), Civil Works

Main Eq.: n°1 AE 94.3A GTG

MONCALIERI District Heating – 400 MW CCHP Repowering

Location: Turin, Italy

Client: Iren Energia

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for BOP, District Heating System (260MWT), Summer Cooler (340MWt), Civil Works

Main Eq.: n°1AE 94.3A GTG

ACEA ELECTRABEL – 400 MW CHP

Location: Leinì, Italy

Client: Ansaldo Energia

Role: Sub Contractor

Scope of Supply: EPC Lump Sum for BOP, District Heating System (170MWt), Water Treatment, Civil Works

Main Eq.: n°1AE 94.3A GTG

TIRRENO POWER – 800 MW CCPP

Location: Vado Ligure, Italy

Client: Ansaldo Energia

Role: Sub Contractor

Scope of Supply: EPC Lump Sum for BOP, Sea Water System, Civil Works

Main Eq.: n°2AE 94.3A GTG

METALS & MINING PLANTS

FATA has successfully executed several EPC Projects for aluminium smelters and complete rolling mills. Thanks to this experience and to strategic alliances with technology licensors and providers, FATA is the ideal partner in executing EPC Metal & Mining Projects such as:

In 2018 FATA signed a strategic Cooperation Agreement with Emirates Global Aluminium (EGA), one of the main primary aluminium producers in the world and the leading Reduction Technology Licensor.

The purpose of the agreement is to cooperate on the development of Aluminium Smelter Projects, combining the state of the art, reliable and energy efficient technology for reduction cells from EGA with FATA’s capabilities in delivering aluminium smelters on an EPC basis.

GDI – Platinum Concentrating Plant

Location: Chegutu District, Zimbabwe

Client: Great Dyke Investments

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key

Main Eq.: Ore handling and crushing section (including SAG mill, Ball mill, Tertiary mill), Floatation sections (rougher, cleaner, re-cleaner, scavenger) with reagent handing systems, Concentrate handling systems (incl. no 2 Filter presses), Tailings handling systems

OARC – Aluminium Rolling Mill 140,000 t/y Sheet Products

Location: Sohar, Oman

Client: Oman Aluminium Rolling Co.

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key forwhole plant

Main Eq.: Melting & holding furnaces, Continuous caster, Hot & Cold Rolling Mill, Coil Annealing furnaces, Tension Leveling Line, Slitting Line, Metal treatment equipment, Cooling water plant

QATALUM – Casthouse 625.000 t/y of Extrusion Billets & Alloy Ingots

Location: Mesaieed, Qatar

Client: Qatalum

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key forwhole plant

Main Eq.: n°11 Furnaces, n°2 VDC Casting lines, n°3 Ingot casting lines, Batch and continuous homogenizing lines, Metal treatment equipment, Metal fluxing stations, Tapping vehicles, Crucible cleaning, Cooling water plant

QATALUM – Anode Bake Furnace 330.000 t/y of Baked Anodes

Location: Mesaieed, Qatar

Client: Qatalum

Role: Main Contractor

Scope of Supply: EPC LSTK forwhole plant

Main Eq.: Baking Furnace A&B with 116 section & 7 fires, n°4Furnace tending assemblies, Fume treatment plant, Green & baked anode storages, n°2Automatic anode cranes, Anode conveying system, Slot cutting machines

HORMOZAL – Complete Aluminium Smelter 147.000 t/y

Location: Bandar Abbas, Iran

Client: Hormozal Aluminium

Role: Main Contractor

Scope of Supply: EPC LSTK forwhole plant

Main Eq.: n°1Potline of 228 pots (EGA Technology), HV Substation, Alumina Storage and Pot feeding, n°2Gas treatment, n°7 PTM Cranes, Pot dig out and repair facility, Anode Baking Plant, Casthouse expansion, MV/LV Power distribution and Utilities

SAYANAL – Aluminium Rolling Mill 44.000 t/y of Sheet & Foil Products

Location: Sayanagorsk, Russia

Client: Sayanal

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for whole plant

Main Eq.: n°3 Melting and holding furnace, n°3 Continuous casting line, Metal treatment equipment, Cold Rolling Mill, Roughing Mill, Intermediate Mill, Universal Mill, Finishing Mill, Coil and Foil Annealing furnaces, Doubling machine

DIVERSIFIED PLANTS

The experience matured in EPC projects within the power generation and metals sectors, the high engineering capabilities and flexibility and the strategic partnership with technology licensors and providers allow FATA to propose itself as a reputable and reliable EPC contractor in diversified industrial sectors including:

ALBA – Port Capacity Upgrade

Location: Sitrah, Baharain

Client: Aluminium Bahrain B.S.C

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key

Main Eq.: Jetty extension works, construction of new silos, new material handling facilities, upgrade of existing equipment for additional alumina and coke handling capacity

GULF CHLORINE – Chlor Alkali Plant

Location: Mesaieed, Qatar

Client: Gulf Chlorine Co.

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for whole plant

Main Eq.: Process & Utilities Plants for 70 MTPD caustic soda as 50% lye or as solid flakes, n° 2 35 MTPD of 32,5% hydrochloric acid, Hydrogen generators to minimize the production of sodium hypochlorite

UNION CHLORINE – Chlor Alkali Plant

Location: Abu Dhabi, UAE

Client: Union Chlorine Co.

Role: Main Contractor

Scope of Supply: EPC Lump Sum Turn-key for whole plant

Main Eq.: Process & Utilities Plants for 70 MTPD caustic soda as 50% lye, 45 MTPD caustic soda as solid flakes, n°2 35 MTPD of 32,5% hydrochloric acid, 7 MTPD sodium hypochlorite